Introduction:

In the world of engineering and technology, control cables play a crucial role in ensuring the efficient operation of various systems and machinery. High flex life control cables, in particular, are designed to withstand continuous bending and flexing without compromising their performance. These specialized cables are used in a wide range of applications, from robotics and automation to medical devices and aerospace equipment. In this article, we will delve into the intricacies of high flex life control cables, exploring their construction, properties, applications, and the numerous benefits they offer to various industries.

1. Understanding High Flex Life Control Cables:

High flex life control cables are specially designed cables that are engineered to endure repeated bending and flexing cycles without undergoing mechanical failure. Unlike standard control cables, which may break or degrade when subjected to continuous bending, high flex life cables are constructed using materials and design techniques that enhance their flexibility and durability. These cables are typically used in applications where frequent movement, articulation, or repetitive motions are required, such as robotic arms, industrial automation systems, and medical equipment.

2. Construction of High Flex Life Control Cables:

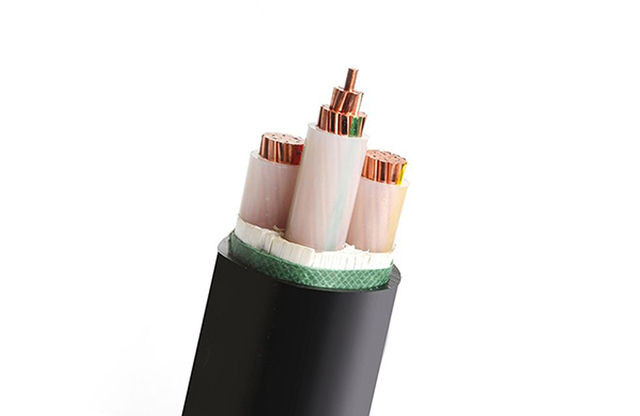

The construction of high flex life control cables is crucial to their ability to withstand constant bending and flexing. These cables are typically composed of several key components, each playing a specific role in enhancing their flexibility and durability. Some of the common components found in high flex life control cables include:

- Conductors: The conductors in high flex life control cables are typically made of high-quality materials such as copper or aluminum, which offer excellent conductivity and flexibility. These conductors are insulated to prevent short circuits and ensure reliable signal transmission.

- Insulation: The insulation in high flex life control cables is designed to withstand repeated bending and flexing without cracking or deteriorating. Specialized materials such as polyurethane, silicone, or fluoropolymers are often used to provide high flexibility and resistance to mechanical stress.

- Shielding: High flex life control cables may also feature shielding components such as braided shields or foil shields to protect the signal integrity from electromagnetic interference (EMI) and radio frequency interference (RFI). Shielding helps ensure reliable data transmission in noisy industrial environments.

- Jacketing: The outer jacket of high flex life control cables is designed to provide additional protection against abrasion, moisture, chemicals, and other environmental factors. The jacket material is selected based on the specific application requirements, ensuring long-term durability and performance.

3. Properties of High Flex Life Control Cables:

High flex life control cables exhibit several key properties that make them ideal for applications requiring continuous bending and flexing. Some of the essential properties of high flex life control cables include:

- Flexibility: High flex life control cables are engineered to be highly flexible, allowing them to bend and twist without experiencing mechanical failure. This flexibility is essential for applications where the cable is subjected to repeated movements or articulation.

- Durability: The materials used in high flex life control cables are selected for their durability and resistance to mechanical stress. These cables can withstand thousands to millions of bending cycles without losing their electrical conductivity or mechanical integrity.

- Signal Integrity: High flex life control cables are designed to maintain reliable signal transmission even under harsh operating conditions. The insulation and shielding components of these cables help minimize signal loss and interference, ensuring accurate data transmission.

- Temperature Resistance: Many high flex life control cables are designed to operate over a wide temperature range, from extreme cold to high heat. This temperature resistance allows these cables to be used in diverse environments, including aerospace, automotive, and industrial applications.

4. Applications of High Flex Life Control Cables:

High flex life control cables find applications across a wide range of industries and sectors due to their flexibility, durability, and reliability. Some of the common applications of high flex life control cables include:

- Robotics: High flex life control cables are extensively used in robotic systems, including articulated robot arms, gantry robots, and collaborative robots (cobots). These cables enable precise motion control and communication between different robotic components.

- Mineral Insulated Cable : In industrial automation systems, high flex life control cables play a critical role in connecting sensors, actuators, motors, and controllers. These cables help streamline the operation of automated machinery and production lines, improving efficiency and productivity.

- Medical Devices: High flex life control cables are utilized in various medical devices and equipment, such as surgical robots, imaging systems, and patient monitoring devices. The flexibility and reliability of these cables are essential for ensuring accurate and safe operation in healthcare settings.

- Aerospace: High flex life control cables are employed in aerospace applications, including aircraft control systems, avionics, and satellite communication systems. These cables must meet stringent performance requirements to withstand the harsh conditions of space and aviation environments.

- Automotive: High flex life control cables are used in automotive applications for connecting sensors, actuators, and electronic control units (ECUs). These cables help facilitate communication between different vehicle components, enhancing safety, performance, and fuel efficiency.

- Industrial Machinery: High flex life control cables are integral to various industrial machinery and equipment, such as CNC machines, packaging systems, and material handling systems. These cables ensure reliable data transmission and control in demanding manufacturing environments.

5. Benefits of High Flex Life Control Cables:

High flex life control cables offer numerous benefits to manufacturers, engineers, and end-users in diverse industries. Some of the key benefits of using high flex life control cables include:

- Increased Reliability: High flex life control cables are designed to withstand continuous bending and flexing, ensuring reliable performance over an extended service life. This reliability minimizes downtime and maintenance costs associated with cable failures.

- Improved Flexibility: The high flexibility of these cables allows for greater freedom of movement and articulation in applications requiring dynamic motion. High flex life control cables can bend, twist, and stretch without compromising their functionality, making them ideal for complex systems.

- Enhanced Signal Integrity: High flex life control cables maintain consistent signal integrity even in high-flex applications, ensuring accurate data transmission and communication. These cables help minimize signal loss, noise, and interference, leading to more reliable operation.

- Longevity: High flex life control cables are built to withstand thousands to millions of bending cycles, making them durable and long-lasting. The robust construction of these cables ensures a prolonged service life, reducing the need for frequent replacements.

- Versatility: High flex life control cables are available in various configurations, sizes, and designs to suit a wide range of applications and requirements. Manufacturers can choose from different cable types and materials to meet specific performance criteria and environmental conditions.

- Cost-Effectiveness: While high flex life control cables may have a higher initial cost compared to standard cables, their durability and reliability can result in long-term cost savings. The reduced maintenance, downtime, and replacement costs associated with these cables make them a cost-effective investment.

Conclusion:

High flex life control cables are essential components in modern engineering and technology, enabling reliable data transmission, motion control, and communication in a variety of applications. These specialized cables offer unparalleled flexibility, durability, and reliability, making them ideal for industries such as robotics, automation, aerospace, and healthcare. By understanding the construction, properties, applications, and benefits of high flex life control cables, engineers and manufacturers can harness the full potential of these advanced cable solutions to enhance the performance and efficiency of their systems.